Heat shrink tubing is a versatile and effective solution for insulating, protecting, and bundling electrical wires and other materials. Its unique properties make it a preferred choice in various industries. Here’s why heat shrink tubing is often chosen over other applications:

Heat shrink tubing is a versatile and effective solution for insulating, protecting, and bundling electrical wires and other materials. Its unique properties make it a preferred choice in various industries. Here’s why heat shrink tubing is often chosen over other applications:

1. Superior Insulation and Protection

- Electrical Insulation: Heat shrink tubing provides excellent dielectric strength, making it ideal for protecting electrical connections from short circuits or external interference.

- Environmental Protection: It shields wires and components from moisture, dust, chemicals, and abrasion, ensuring durability in harsh environments.

2. Secure Fit

- Customizable Tightness: When heated, the tubing shrinks to fit snugly around the object, creating a secure seal that other methods, like tape or wraps, cannot achieve.

- Variety of Sizes: Available in different shrink ratios (e.g., 2:1, 3:1), it accommodates various cable and connector sizes for a tailored fit.

3. Ease of Use

- Quick Application: Applying heat shrink tubing is straightforward—just slide it over the area and apply heat with a heat gun or lighter.

- Minimal Tools Required: Unlike adhesive tapes or clamps, heat shrink does not need extensive tools or effort to apply effectively.

4. Durability and Longevity

- Resistance to Wear: Heat shrink is resistant to punctures, UV light, and temperature fluctuations, making it suitable for long-term applications.

- Fire Retardant Options: Some heat shrink tubing is designed to be flame-retardant, adding an extra layer of safety.

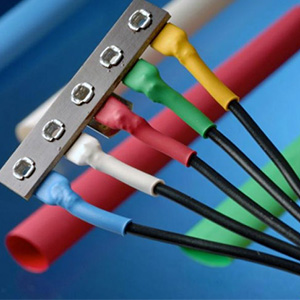

5. Professional Appearance

- Clean Finish: Heat shrink tubing offers a sleek and organized look, often used in applications where aesthetics and professionalism are important.

- Color-Coding: Available in multiple colors, it allows for easy identification and organization of cables.

6. Versatility

- Multiple Uses: Beyond wires, heat shrink can be used to bundle cables, seal connectors, repair damaged insulation, and even provide strain relief in mechanical components.

- Wide Application Range: Suitable for industries including automotive, aerospace, marine, telecommunications, and consumer electronics.

Why Choose Heat Shrink Over Alternatives?

While other options like electrical tape, wire loom, or cable ties serve specific purposes, they often fall short in providing the same level of insulation, protection, and professional finish as heat-shrink tubing. For applications requiring a long-lasting and reliable solution, heat shrink stands out as the superior choice.