Cable entry seals play a crucial role in protecting electrical systems and enclosures from environmental hazards like dust, moisture, and temperature changes. Whether you’re new to the world of cable management or looking to upgrade your current setup, this beginner’s guide will explain everything you need to know about cable entry seals.

Cable entry seals play a crucial role in protecting electrical systems and enclosures from environmental hazards like dust, moisture, and temperature changes. Whether you’re new to the world of cable management or looking to upgrade your current setup, this beginner’s guide will explain everything you need to know about cable entry seals.

What Are Cable Entry Seals?

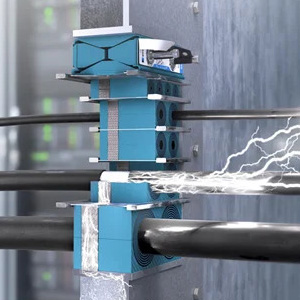

Cable entry seals are protective barriers designed to safeguard cables where they pass through walls, enclosures, or equipment panels. They form a tight seal around the cable, preventing contaminants like water, dust, and air from entering the system, which can damage sensitive electronics or cause system failures.

Why Are Cable Entry Seals Important?

- Environmental Protection: By keeping out moisture, dust, and other elements, cable entry seals help prevent corrosion and short circuits, prolonging the lifespan of your equipment.

- Maintaining System Efficiency: Sealing cable entry points prevents temperature fluctuations and humidity from affecting the system’s performance.

- Enhanced Safety: By reducing exposure to the elements, cable entry seals minimize the risk of electrical hazards, creating a safer working environment.

Types of Cable Entry Seals

- Grommet Seals: Flexible, rubber-like seals that are pushed into a hole to allow cables to pass through. They are ideal for protecting cables from wear and tear caused by vibration or movement.

- Compression Seals: These seals use mechanical pressure to create a tight fit around the cable. Compression seals are often used in industrial settings where a strong, water-tight seal is essential.

- Multi-cable Entry Seals: These allow multiple cables to pass through a single opening while maintaining a seal around each cable. They are highly efficient for complex installations.

- Heat Shrink Seals: Made of a material that shrinks when heated, forming a tight seal around the cable. Heat shrink seals are common for both electrical and environmental protection.

How to Choose the Right Cable Entry Seal

- Material: Different environments require different materials. For example, silicone or rubber seals are suitable for general use, while stainless steel is ideal for more corrosive or extreme environments.

- Size: Measure the diameter of the cable and the entry point to ensure a proper fit. Too loose, and the seal won’t protect; too tight, and you risk damaging the cable.

- Ingress Protection (IP) Rating: Check the IP rating of the seal. For outdoor or industrial applications, a high IP rating (IP67 or IP68) is recommended for waterproof and dustproof protection.

- Application Needs: For dynamic environments where cables might move, opt for flexible seals like grommets. In static installations, compression or heat shrink seals may provide better protection.

Installation Tips for Cable Entry Seals

- Prepare the Surface: Ensure the surface where the seal will be installed is clean and free from debris to create a solid seal.

- Follow Manufacturer Instructions: Different types of seals may have specific installation steps. Always follow the manufacturer’s guidelines to ensure proper application.

- Double-check for Leaks: After installation, it’s a good idea to test the seal by exposing it to water or pressure, depending on the environment it will be used in, to ensure it’s properly secured.

Where Are Cable Entry Seals Used?

- Telecommunication Cabinets: Protecting sensitive wiring from outdoor elements.

- Marine Vessels: Ensuring water-tight protection for electrical systems.

- Automotive Industry: Sealing cables in vehicles to prevent damage from road debris and moisture.

- Industrial Plants: Securing heavy-duty cables in environments with extreme temperatures, moisture, or hazardous materials.

Conclusion

Cable entry seals are an essential part of protecting any system with cables running through exposed areas. By choosing the right type of seal and installing it correctly, you can ensure the longevity, safety, and efficiency of your electrical or data systems.