Heat shrink tubing is a versatile, easy-to-use material that provides excellent protection, insulation, and reinforcement for electrical connections, wires, and even delicate components. This beginner’s guide will walk you through the fundamentals of heat shrink, including what it is, how it works, its different types, and common applications.

Heat shrink tubing is a versatile, easy-to-use material that provides excellent protection, insulation, and reinforcement for electrical connections, wires, and even delicate components. This beginner’s guide will walk you through the fundamentals of heat shrink, including what it is, how it works, its different types, and common applications.

What is Heat Shrink?

Heat shrink is a plastic tubing that shrinks in size when exposed to heat, creating a tight seal around wires or other materials. Typically made from polyolefin or PVC, heat shrink tubing offers durable protection from environmental factors such as moisture, dust, chemicals, and abrasion. It also improves electrical insulation, making it ideal for use in various industries like automotive, aerospace, marine, and electronics.

How Does Heat Shrink Work?

Heat shrink tubing is designed to shrink down to a pre-determined size when heated. When applied to wires or other components, you heat the tubing (using a heat gun or lighter) and watch it conform tightly to the shape of the underlying material. The material’s shrink ratio varies depending on the tubing, typically ranging from 2:1 to 4:1. For example, a 2:1 ratio means the tubing will shrink to half its original size once heated.

Types of Heat Shrink Tubing

Heat shrink tubing comes in various types, each suited to different applications. Here are the most common types:

- Standard Polyolefin Heat Shrink: The most widely used heat shrink tubing due to its flexibility, durability, and resistance to chemicals and UV light. It’s often used in electrical insulation and wire bundling.

- Adhesive-Lined Heat Shrink: Also called dual-wall heat shrink, it has an inner adhesive layer that melts during heating, forming a watertight seal. It’s excellent for moisture protection and cable repair.

- Flame-Retardant Heat Shrink: Designed for environments with high fire risks, this tubing reduces the spread of flames and is typically used in aerospace or automotive industries.

- PTFE Heat Shrink: Known for its high heat resistance, PTFE (Teflon) tubing is used in applications involving extreme temperatures, chemical exposure, or medical devices.

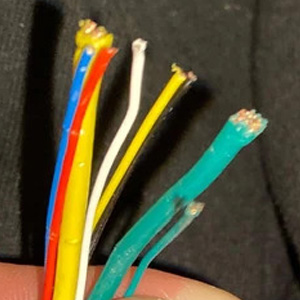

- Colored Heat Shrink: Available in a variety of colors, this tubing is often used for color-coding wires or organizing complex wiring systems.

Common Applications of Heat Shrink Tubing

Heat shrink tubing is highly versatile and can be used in many fields. Here are some of its most common uses:

- Wire Insulation: Heat shrink provides a protective layer over exposed wires and connections, preventing electrical shorts or damage from environmental exposure.

- Cable Repair: Damaged cables can be repaired and reinforced using heat shrink tubing, extending their lifespan.

- Strain Relief: Adding heat shrink to cable ends or connectors prevents bending and pulling that could damage wires or connections.

- Environmental Protection: Heat shrink offers protection against moisture, dust, chemicals, and other contaminants, making it ideal for outdoor or industrial use.

- Automotive and Marine Applications: In vehicles and boats, heat shrink tubing is used to protect wires from moisture, saltwater, and extreme temperatures, keeping electrical systems intact.

- Bundling Wires: Instead of using zip ties, heat shrink can bundle wires for a cleaner and more organized look while providing protection.

How to Use Heat Shrink Tubing

Using heat shrink tubing is a straightforward process. Here’s a step-by-step guide:

- Measure and Cut: Select the appropriate size of tubing based on your wire or component. Measure the length needed and cut the tubing slightly longer than the area you’re covering.

- Slide Tubing Over the Wire: Before making connections or crimping wires, slide the heat shrink tubing onto the wire or component.

- Apply Heat: Use a heat gun, lighter, or other heat sources to evenly apply heat to the tubing. Move the heat source back and forth to ensure even shrinkage without burning the tubing.

- Inspect the Fit: The tubing should shrink tightly around the material, leaving no gaps. If using adhesive-lined heat shrink, ensure the adhesive melts and seals the tubing for a watertight finish.

Choosing the Right Heat Shrink

When choosing heat shrink tubing, consider these factors:

- Shrink Ratio: A higher ratio allows the tubing to shrink to a smaller size, useful for irregularly shaped components.

- Diameter: Choose tubing with a diameter that fits snugly around your wires or components before shrinking.

- Material: Select a material based on the environment (e.g., high temperature, moisture, chemical exposure).

- Color: For color coding or aesthetics, choose the appropriate color to match your needs.

Conclusion

Heat shrink tubing is an essential tool for protecting, insulating, and reinforcing electrical components and wires. Whether you’re working on automotive repairs, electronics, or even DIY projects, understanding the different types and applications of heat shrink will help you select the best option for your needs. Remember to always choose the correct size and material, and follow the proper procedure for application to ensure a secure and lasting fit.