Heat shrink connectors are widely used in electrical wiring for their ability to provide secure, waterproof, and insulated connections. They are particularly valued in automotive, marine, and other environments where durability and resistance to moisture are crucial. Here’s a detailed look at how heat shrink connectors work:

Heat shrink connectors are widely used in electrical wiring for their ability to provide secure, waterproof, and insulated connections. They are particularly valued in automotive, marine, and other environments where durability and resistance to moisture are crucial. Here’s a detailed look at how heat shrink connectors work:

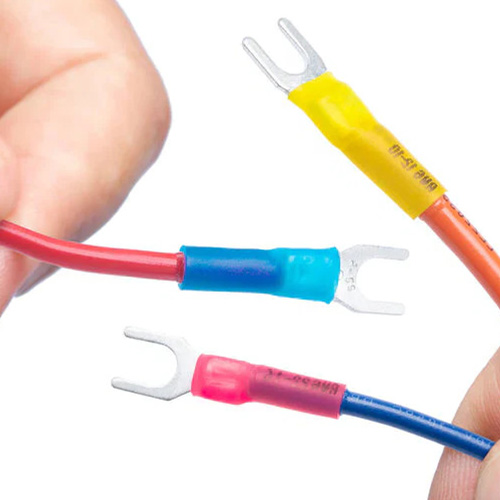

Components of Heat Shrink Connectors

- Metal Connector: At the core of a heat shrink connector is the metal connector, typically made of copper or a copper alloy, which ensures good electrical conductivity. This part is often a crimp or solder type where the wires are physically joined.

- Heat Shrink Tubing: Surrounding the metal connector is a layer of heat shrink tubing, usually made of polyolefin. This tubing is designed to contract when heated.

- Adhesive Lining: Many heat shrink connectors also feature an adhesive lining inside the tubing. This adhesive melts and flows when heated, creating a watertight seal around the connection.

How They Work

- Stripping the Wires: The process begins by stripping the insulation from the ends of the wires to be connected. This exposes the conductive metal cores.

- Inserting the Wires: The exposed wire ends are inserted into the metal connector. Depending on the type of connector, this might involve crimping (using a crimping tool to press the connector onto the wires) or soldering (melting solder to join the wires to the connector).

- Applying Heat: Once the wires are securely attached to the metal connector, heat is applied to the heat shrink tubing. This is usually done with a heat gun, although other heat sources like a lighter or torch can be used with caution.

- Shrinking Process: The heat causes the tubing to contract, or “shrink,” tightly around the connection. As the tubing shrinks, it conforms to the shape of the wires and the connector, creating a snug fit.

- Sealing: If the heat shrink tubing has an adhesive lining, the heat also melts the adhesive. As the tubing shrinks, the adhesive flows and fills any gaps, providing a seal that is resistant to moisture, chemicals, and physical abrasion.