Heat shrink tubing is a versatile and effective method for strain relief in electrical and mechanical connections. By using heat shrink, you can secure, protect, and reinforce connections, ensuring they last longer and withstand stress and wear.

Heat shrink tubing is a versatile and effective method for strain relief in electrical and mechanical connections. By using heat shrink, you can secure, protect, and reinforce connections, ensuring they last longer and withstand stress and wear.

How It Works:

- Application: Slide the heat shrink tubing over the area where strain relief is needed. This could be the point where a wire meets a connector, or where a cable may experience frequent bending.

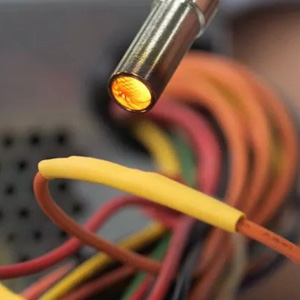

- Heating: Using a heat gun, the tubing shrinks to fit tightly around the wire or connector. As it shrinks, it conforms to the shape of the item it surrounds, creating a secure, protective layer.

- Reinforcement: Once shrunk, the tubing provides added thickness and stiffness, which helps reduce strain and movement at the connection point. This is especially useful in areas where wires are likely to bend or flex repeatedly.

Benefits of Heat Shrink for Strain Relief:

- Prevents Wire Fraying and Breaking: The tubing absorbs stress that might otherwise damage the connection.

- Improves Durability: Adds a protective layer against abrasion, moisture, and chemicals, enhancing the longevity of the connection.

- Insulates and Protects: Provides additional insulation, which is crucial for electrical connections.

- Neat and Professional Finish: Heat shrink tubing helps keep wires organized and provides a clean look to the final assembly.

Choosing the Right Heat Shrink Tubing:

- Diameter: Ensure the tubing diameter is appropriate for the wire size. It should be large enough to slide on easily but shrink tightly around the connection.

- Shrink Ratio: Choose tubing with a suitable shrink ratio (e.g., 2:1 or 3:1) for a secure fit after shrinking.

- Material and Temperature Resistance: Some heat shrink tubing is made for specific environments, including high heat or exposure to chemicals.

Using heat shrink tubing for strain relief is a simple, effective way to reinforce and protect your connections, making them more durable and reliable in both routine and demanding applications.